Tšimo ea Kopo

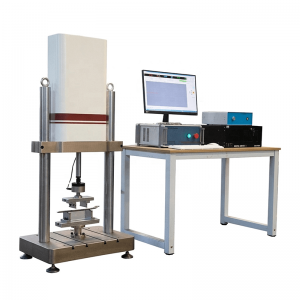

Setifikeiti sa Electro-hydraulic sertiou Mochini oa tlhahlobo o ka etsa liteko tse latelang:

Tlhahlobo ea tensitse le khatello ea maikutlo

Teko ea kholo ea Crack

Sistelli ea Loco-Loop e koahetsoeng e entsoe ka molaoli oa motlakase, sensoko, sensor, e ka lekanya litekanyetso tsa liteko, ka boeona. angle.

Mochine oa tlhahlobo o khona ho bona Sine Wave, Triangle Wave, Square Wave, Oni-Wilse, Comcle E ka boela ea fuoa sesebelisoa sa liteko tsa tikoloho ho phethela liteko tsa tlhaho tsa tlhaho tsa tlhaho.

Mochine oa tlhahlobo o fetoha le maemo ebile ho loketse ho sebetsa. Ho phahama ha beam ho phahamisa, ho notlela, le ho hlakoloa ha motho ho tla phethetsoe ka ts'ebetso ea konopo. E sebelisa theknoloji ea hydraulic ea hydraulic ho ea mojarong Boleng le ho fallisoa. Tekanyo ea digital ea dijithale le tsamaiso ea taolo e hlokomela taolo ea matla, deformation le ho fallisoa, 'me taolo e' ngoe le e 'ngoe e ka hlahisoa hantle. , Software ea liteko e sebetsa ka lifensetere tsa chinese xp / Win7 Ts'ebetso ea tlhahlobo e kopantsoe ka botlalo taolo ea k'homphieutha. The test machine is an ideal cost-effective test system for scientific research institutes, metallurgical construction, national defense and military industry, universities, machinery manufacturing, transportation and other industries.

Litlhaloso

| Mohlala | Pws-25kn | Pws-100kn |

| Matla a Teko ea Teko | 25kn | 100KN |

| Tekanyetso ea Tekanyetso ea Teko ea Teko | 1/180000 | |

| Leka ho nepahala ha qobang | ka har'a ± 0.5% | |

| Mekhahlelo ea Tlhaho | 0 ~ 150 (± 75) (mm) | |

| Karolo e lekanyang | 0.001mm | |

| Phoso e amanang ea ho fana ka mokhoa oa ho lekola boleng | ka har'a ± 0.5% | |

| Khatiso ea Nako | 0.01 ~ 100hz | |

| Khatiso e tloaelehileng ea liteko | 0.01-50hz | |

| Teko ea Waveforms | Slave Wave, Triangle Wave, Half Me Suve, Half Me Wave, Half Costine Wave, Half Krine Wave | |

| Sebaka sa liteko (ntle le ho khetheha) mm | 1600 (e ka etsoa) | |

| Bophara bo Sebetsang kahare | 650 (e ka etsoa) | |

Tloaelo

1) GB / t 2611-2007 "Litlhokahalo tsa kakaretso tsa Tekelo ea Tekelo ea Teko bakeng sa Mechini ea Teko"

2) GB / T16825.1-2008 "Tlhahlobo ea mochini oa khatello ea kelello o sa feleng

3) GB / T 16826-2008 "Seticro-hydraulic Settic Settiver ea liteko tsa liteko"

4) JB / T 8614-1997 "Setifikeiti sa Tekanyetso ea Elecro

5) JB9997-2002

6) GB / T 3075-2008 "Mokhoa oa Teko ea Teko ea Metal Axage ea Teko ea Metal"

7) GB / T15248-2008-2008-2008-2008-2008-2008-2008-2008-2008

8) GB / t21143-2007

9) hg / t 2067-1991 Teropo ea mochini oa terene

10) ASTM E466 Teko ea Tlhahlobo ea Kic Bakeng sa Liner Elaar Elaar e Lifofane tsa Lifofane tsa Linear Lifofane tsa Tefo ea Metallic

11) ASTM E1820 2001 Jic Test Standard bakeng sa ho ba mabifi

LINTHO TSE HLAHANG

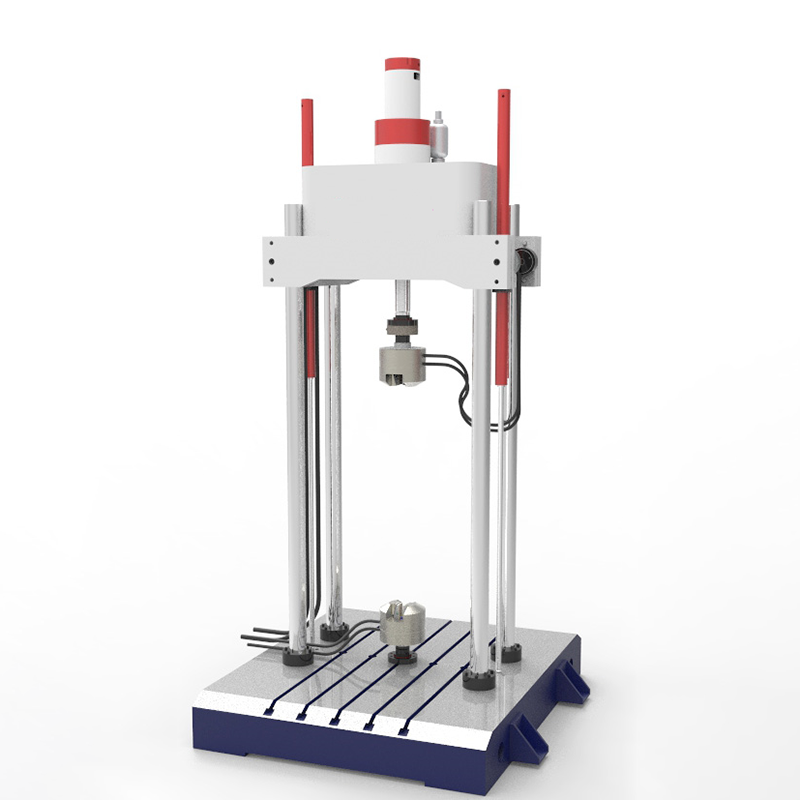

Motho a le mong:Moamoheli o entsoe ka foreimi e tsamaisang, kopano e kaholimo ea axalia, e nang le matla a motlakase oa hydraulic, mohloli oa oli ea hydraulic, ho leka-lekanya le lisebelisoa tsa liteko.

2

Mokhabiso oa mochini o ka sehloohong o entsoe ka lintlha tse 'maloa, maballo a tsamaeang le mosebetsi ho theha forantšu se koetsoeng. Sebopeho se kopaneng, seriti se phahameng le karabelo e matla.

2.1 bokhoni ba axal e nang le axial: ≥ 100kn;

2.2 Beam e susumetsang: Ho phahamisa hydraulic, ho hlohlona hoa hydraulic;

Sebaka sa Teko: 650 × 1600Mmm

2.4 Sensor sansor: (Qianli)

2.4.1 litlhaloso tsa sensor: 100kn

2.4.2 Kananeono oa kutlo: ± 0.1%;

2.4.3 Sensor everload: 150%.

3 hydraulic seval linear linear musiator:

3.1 Kopano ea Actiator

3.1.1 Sebopeho se kopaneng:

3.1.2 Likarolo: Ho kenngoa ka mokhoa o kopanetsoeng ho khutsisa ketane ea moroalo, ntlafatsa lekhalo la moroalo, le ntlafatsa lesiti la moroalo, le ntlafatsa lesika la tsamaiso, 'me le na le khatello e ntle ea potoloho ea morao.

3.1.3 Khakolohing ea ho fumana khafetsa: 0.01 ~ 100hz (khafetsa ea tlhahlobo hangata ha e fetele 70hz);

3.1.4 Phetoho:

a. Mohala oa Linear: 1

I. Sebopeho: Double Rod habeli sebopeho sa symmetrical;

II. Matla a phahameng a liteko: 100 kn;

III. A lekantsoe khatello ea ho sebetsa: 21Luoa;

IV. Piston Stroke: ± 75mm; Tlhokomeliso: Beha sebaka sa hydraulic buffer zone;

b. Setectro-hydraulic seva vala: (Brand ea kantle)

I. Mohlala: G761

II. Phallo e lekantsoeng: 46 l / metsotso e 1

III. Khatello e lekantsoeng: 21Ma

IV. Khatello e sebetsang: 0.5 ~ 31.5 MPA

c. Sensor e le 'ngoe ea ho falla

I. Model: HR Series

II. Ho lekanya likarolo: ± 75mm

III. Qeto: 1um

IV. E senang feela: <± 0.01% ea bongata bo felletseng>

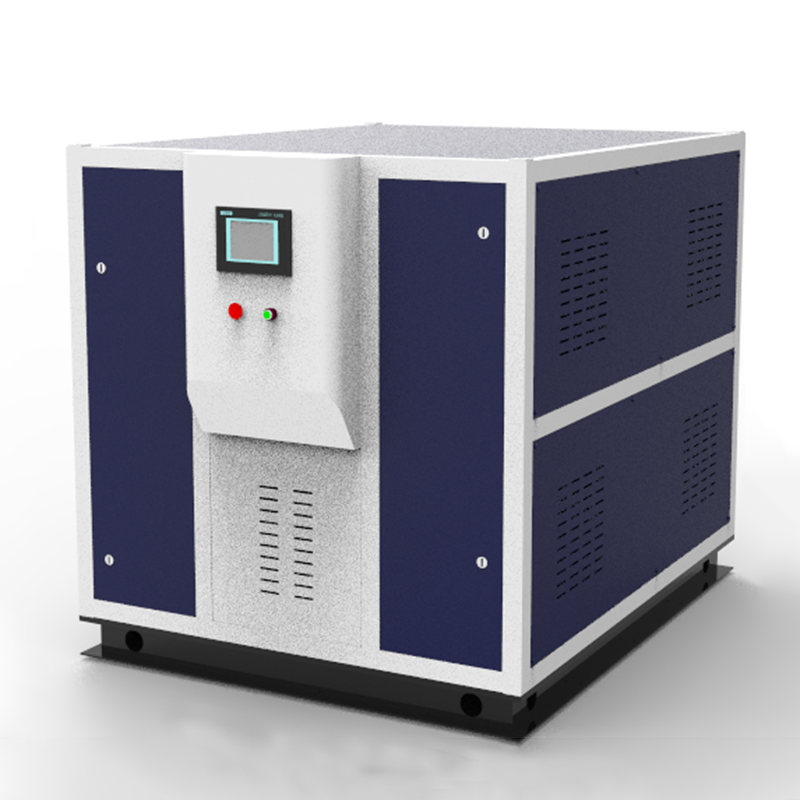

Li-4 tsa hydraulic Sertont Product mohloli oa oli

Seteishini sa pompo ke seteishene sa pompo e tsitsitseng se nang le moralo oa mekhahlelo. Ka mohopolo, e ka oela seteisheneng se seholo se pompang ka phallo efe kapa efe, ka hona e na le sebopeho se setle le tšebeliso e kholo.

Phepelo ho phalla 46l / min, khatello 21Ma. (E fetotsoe ho latela litlhoko tsa liteko)

Power e felletseng ke 22kw, 1050v, karolo e meraro, 50hz, AC.

L · himp seteishene sa pompa se entsoe ka mokhoa o hlophiloeng ho latela sebopeho sa motsoako o tloaelehileng, se nang le theknoloji e holileng tsebong le tšebetsong e holileng; E na le mojule oa litheko tsa voltage ea litheko tse theko e phahameng, e amanang le molaoli.

Seteishene sa pompoing se entsoe ka lipompo tsa oli, motors, li-class tsa libate tse phahameng le tse tlase le tse tlase, litaoana tsa oli, litsamaiso tsa mesebetsi le likarolo tse ling;

L · H · fisishene e alima filimi-mekhahlelo e meraro ea mekhahlelo ea mesebetsi ea oli ea oli, 100μ; Moeli oa khale oa khale, ho nepahala ha ho lokisa 3μ ho nepahetse 3μ; Modula oa litheko tsa voltage o reritural o nepahala 3μ.

Lipumpiri tsa oli li khethoa ho Telford Telford Indepd ea Ka hare, e leng li-adts tse tsoang ka hare tsa gear tsa kahare, tse tlase haholo le bophelo bo bolelele;

Yuniti ea lithuthu sa Pump e na le sesebelisoa se tlohang (khetha ho fokotsa Pad) ho fokotsa ho sisinyeha le lerata;

LPROSE e phahameng le e tlase ea khatello ea khatello ea mathata ho qala le ho emisa sistimi ea hydraulic.

L · FALD STATED STATED STATED STATED STATED STATED STATHER, Bophahamo ba tanka ea mafura ha se ka tlase ho 260l; E na le mesebetsi ea tekanyetso ea mocheso, ho hlophisoa ha moea, pontšo ea boemo ba oli, jj.;

Sekhahla sa L · b · 40l / Min, 21Ma

5. 5 Compled ho eketsa tse tobileng (ka boikhethelo)

5.5.1 Hydraulic e qobelloang e qosa Chuck. sete;

L · HYYDIUS ba qobelloang, khatello ea ho sebetsa 21Ma, e kopana le litlhoko tsa nako e telele le e tlase ea khatello ea maikutlo le khatello ea peo.

Khatello ea ho sebetsa e ka fetoloa, mofuta oa phetoho ke 1mp-21MA;

Sebopeho sa LAN. Ho bonolo ho khutlisa mehlahare.

l · on ea itetseng Names

L · ellong e amohelang mesare ea likhahla tse chitja: 2 litheo; li-sopho tsa li-graws bakeng sa likhatiso tse bataletseng: 2 litheo; (ho atoloha)

5.5.2 Sethala se le seng sa lithuso le liteko:

L · e le 'ngoe ea poleiti e nang le bophara

L · resto ea AIDS e boneng ka makhetlo a mararo bakeng sa tlhahlobo ea kholo ea lefutso.

![Pws-25 / 100kn Dynamic hydraulic Sertigue Teko ea Machine 0-100HH] Setšoantšo](https://cdn.globalso.com/cytester/692c7ed5.png)