Tšimo ea Kopo

Wite ea tšepe, e le mong, bar, tube, pampiri;

Redara, lesela;

Mefuta e malelele ea bolelele, likarolo tse nang le ts'ebetso e kholo le matla a mang a mangata, tšepe e thata;

LINTHO TSE HLAHANG

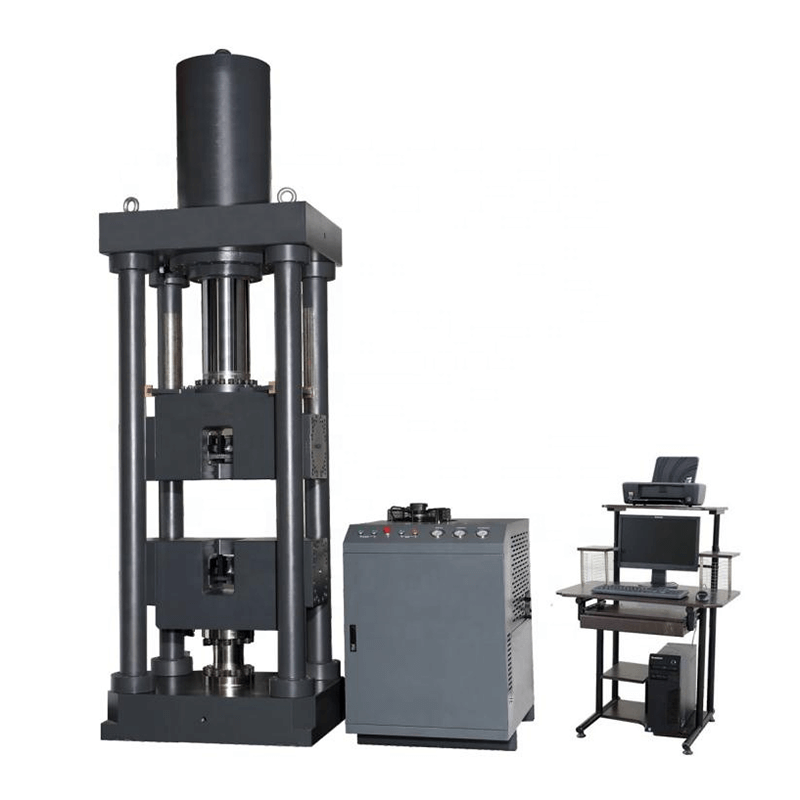

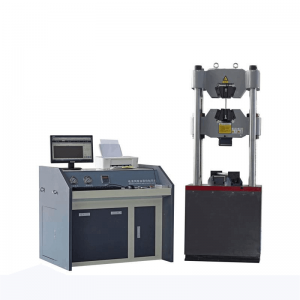

1. Moralo o le mong - moralo o le mong

2. Hydraulic Wedge e fana ka moralo o bulehileng ka kotloloho o lekanyelitsoeng ho imelang ka botlalo ho boloka o sebetsa hantle le ho sireletsehile bakeng sa opareitara;

3. Kholomo e nang le pheko e nang le pheko e nang le pheko e nang le phetisetso e bonolo bakeng sa ho hloekisa habonolo le ea tšoarellang.

4. Lebokose la ts'ebetso la letsoho le etsa hore ts'ebetso e be bonolo le ho fetoha le maemo;

5. Sebaka sa Teko se boima sa Ultra

6. Kamothese ho feta ho ka ba le tlhokomelo ho etsa tlhahlobo e bonolo le ho lekanya ho tšepahala ho feta;

7. Ho nepahala ho phahameng ho tšela sele e leka-lekaneng ka kotloloho

8.

9. Ka ho sebelisa khatello e phahameng ea sebaka sa ka hare, lerata le ka tlase ho 60 DB tlasa mojaro o felletseng;

10.

11. Ka li-averse sterose;

12.

Ho latela molao

E kopa litlhoko tsa naha ea naha ea GB / T228.1-2010 ea Teko ea Teko ea Teko ea Tontive ", GB / T73 Compression

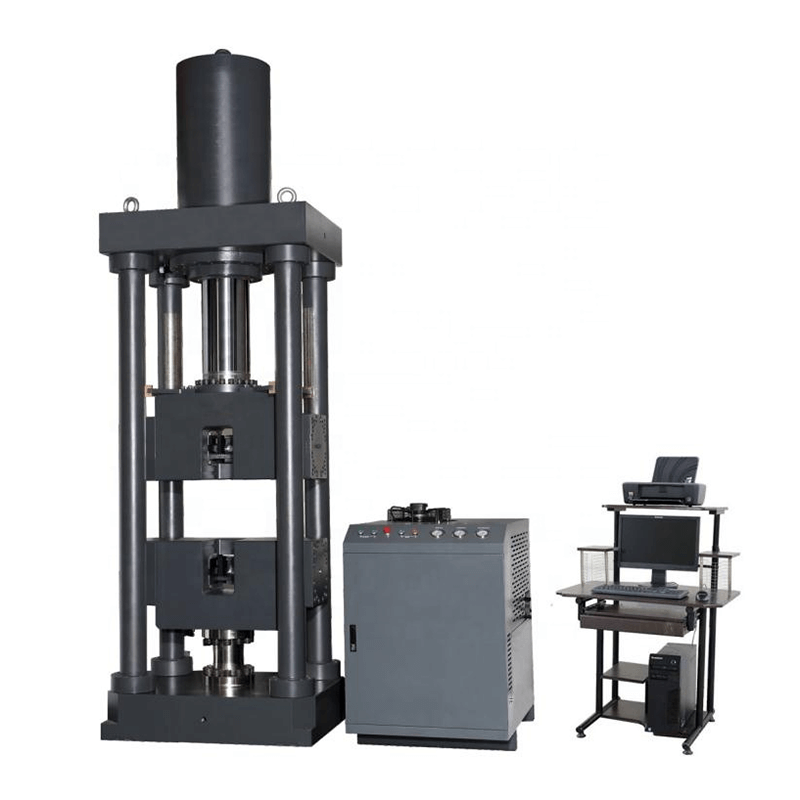

| Matla a Teko ea Tenseile | 3000kn |

| Karolo e sebetsang ea matla a liteko | 2% -100% FS |

| Tekanyo ea taolo ea taolo ea taolo ea matla | ± 1% |

| Hydraulic cylinda cylinda ea Piston | 1000mm |

| Phallo ea kholomo | 800mm |

| Lebelo le phahameng la piston | 0-50mm / Min (stepless lebelo) |

| Ho nepahala ho hongata | Betere ho feta ± 1% |

| Qeto ea ho fallisoa | 0.01mm |

| Ho nepahala ha matšoao a ho fallisoa | ± 1% |

| Sebaka se phahameng sa ho otlolla | 1000mm |