Kopo

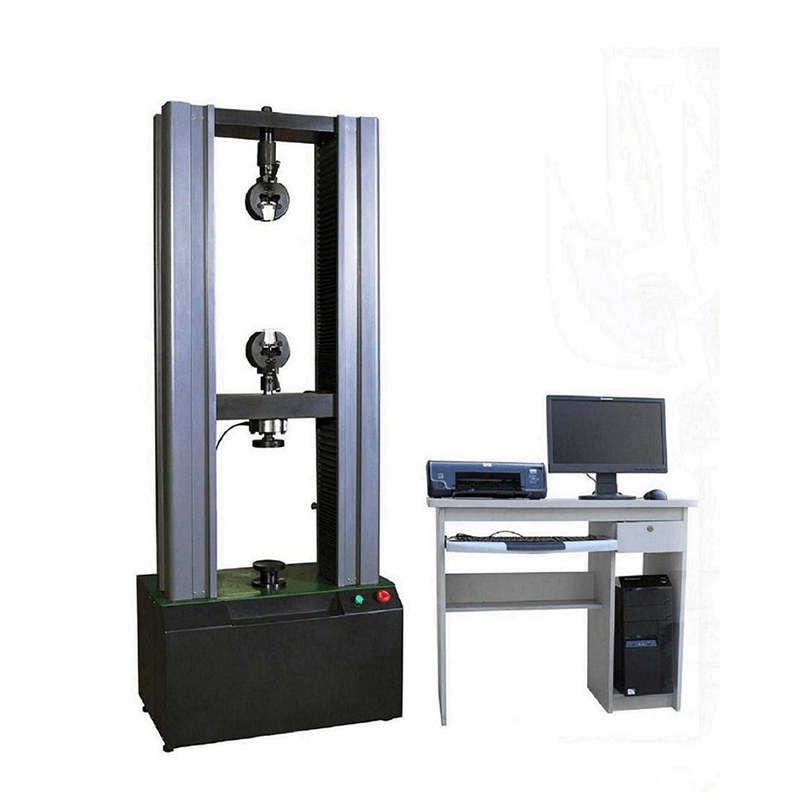

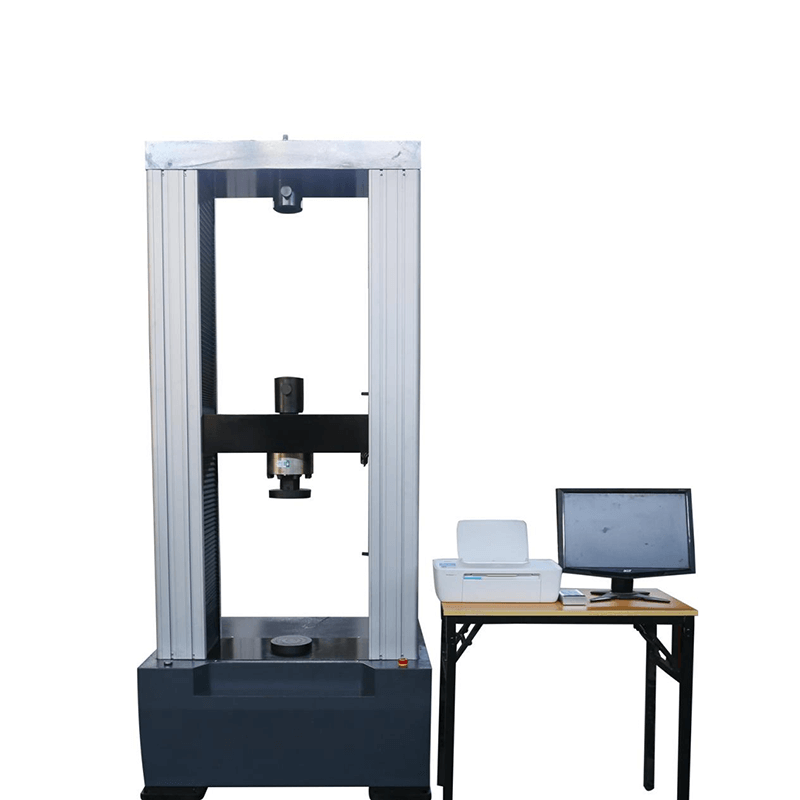

Mechini ena ea liteko e na le software ea komporo, e hatisang ea ho fana ka matla a mangata a tšepe, lipehelo tsa mesifa e sa lekanang. Liphetho tsa liteko li ka hatisa (matla - ho tsoaloa - matla - ts'ebetso ea liteko - e nang le liteko tse amanang le software e ka bang mathata . Ke lisebelisoa tse ntle tsa liteko bakeng sa likhoebo le tsa morato, likarolo tsa lipatlisiso tsa saense, liunivesithi, setsebi sa taolo ea boenjiniere. Tsena ke karolo e phethahetseng ea tlhahiso ea tlhahlobo ea tlhahlobo ea tlhahlobo ea tlhahlobo ea tlhahlobo ea tlhahlobo, liunivesithi le compols, setsi sa lipatlisiso le tsa indasteri le morati.

TLHOKOMELISO

| Khetha mohlala | Wdw-50d | Wdw-100d |

| Matla a Teko ea Teko | 50kn li-tons tse 5 | 100kn 10Ton |

| Boemo ba mochini oa liteko | Boemo ba 0.5 | |

| Tekanyetso ea maemo a lekanyetsoang | 2% ~ 100% FS | |

| Phoso e lekanang ea Sesole sa Sesole | Kamora ± 1% | |

| Phoso e lekanang ea sesupo sa beam | Kahare ho 1 | |

| Qeto ea ho fallisoa | 0.0001mmm | |

| Lenaneo la ho fetola ka lebelo | 0.05 ~ 1000 mm / min (antistic o fetotsoe) | |

| Phoso e lekanang ea lebelo la beam | Ka har'a ± 1% ea boleng bo behiloeng | |

| Sebaka se sebetsang hantle | 900mm Standard (e ka etsoa) | |

| Katleho e sebetsang ea Teko | 400mm Standard (e ka etsoa) | |

| Boholo | 720 × 520 × 1850mm | |

| Taolo ea Moruti ea Servo | 0.75kw | |

| phepelo ea motlakase | 220v ± 10%; 50hz; 1kw | |

| Boima ba Machine | 480kg | |

| Tlhophiso ea mantlha: Metsoako eo eseng e tloaelehileng e ka etsoa ho latela litlhoko tsa sampole ea bareki. | ||

LINTHO TSE HLAHANG

1.Sebopeho se thata sa pele se tsamaisang sethala se nang le sebaka se kaholimo sa tensitse le se tlase bakeng sa compression le tlhahlobo ea ho inama

2.Marang-rang a boloi a hlobolisa ho laolla tsohle ka tšebeliso ea bophelo ba nako e telele le sebopeho se kopane.

3.Tsamaiso ea taolo ea lebelo e behiloe tlasa tafole mme e na le lebanta le nang le phetisetso le pulley bakeng sa lerata le matla le tlhokomelo e tlase.

4.Sefapano se tsitsitseng ka holimo, 'me se lutse ka holim'a foreimi le ka sefapano se bohareng ba le leeto le boreleli ha le ntse le letetse. Sensor e nepahetseng e hlakileng e kentsoe ka tlase ho sefapano.

5.Ho iketsa ka nako ea ho phomola ka ho iketsahalong, khatello ea maikutlo, taolo ea likhohola, taolo ea potoloho le boits'oaro.

6.Phahamisetso e phahameng e beha sensor bakeng sa netefatso e nepahetseng le e tsitsitseng

7.Lebelo la Trassbebeam Travel Travel ho tloha 0.05 ~ 500mm / min

8.Ts'ireletso ea chelete: Ha matla a liteko a feta 2% -5% ea matla a lekang a mangata a file e ngoe le e 'ngoe ea file, e tla emisa.

Tloaelo

Astma370, Astme4, ASTM8, ASTM8, Iso9892, IS10002, GB13-1291, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991, HGT 3991 Gb6349-1986, GB / T 1040.2-2006, ATM C165, EN1606, EN1607, EN1607, EN1607, EN1607, EN1607