Tšimo ea Kopo

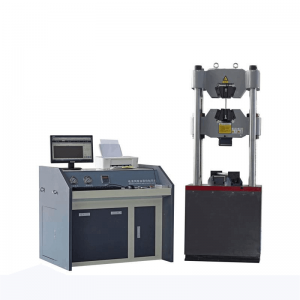

Lenaneo lena la sekala le ikhethileng la tlhahlobo ea tlhahlobo le leretsoeng la PC Pontšo le ho khanna tsamaiso ea li-hydraulip E na le litšobotsi tsa mekhoa ea ts'ebetso, e sebetsa ka mokhoa o tsitsitseng, e phahameng le ho kenya tsitsitseng. E sebelisoa ho otlolla, ho hatella, kotoletsa le ho khaola samente ea tšepe, konkreite, polasetiki joalo ka.

LINTHO TSE HLAHANG

1 tanka ea furu e halikiloe ka tlasa moamoheli, liteko tsa teko li fumaneha kaholimo ho moamoheli, compression, ho chesa le moaho, mekhoa e mengata.

2 Sebopeho se entsoe ka kholomo e mene e tiileng le sekoti se le 'ngoe, mochini oa mochini o na le botsitso bo matla.

3 Moamoheli o etselitsoe tsohle - ka mokhoa o hlakileng ho netefatsa hore o otlolohile matla a matla a matla e le hore e ka hanela sesupo sa micro ha e ntse e eketseha.

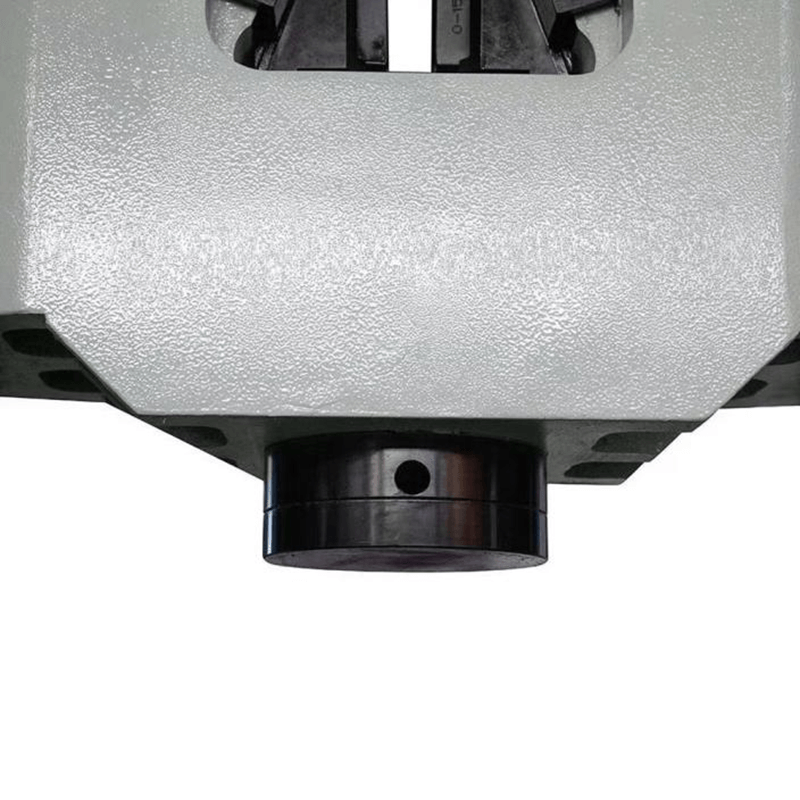

4am e bohareng ba beam e atisa ho fetoleloa ka har'a mochine o ka fetoloang oa gap, ho tlosa lekhalo le ho ntlafatsa ts'ebetso ea tekanyo.

Ho ile ha utloahala ha mafura a mafura a loraliloeng a tiisitsoe, a ntlafatsa ho nepahala ha tekanyo le ho aha bophelo ba tšebeletso.

6 Ha matla a liteko a feta 2% -5% ea matla a sehlotšoana sa faele e 'ngoe le e' ngoe ea tlhahlobo ea faele e 'ngoe le e' ngoe, e jarolla ts'ireletso, e tla emisa.

7 Ha Piston a tsoha sebakeng sa moeli o kaholimo, tšireletso ea maeto, motor pomp se tla emisa.

Ho latela molao

E kopa litlhoko tsa naha ea naha ea GB / T228.1-2010 ea Teko ea Teko ea Teko ea Tontive ", GB / T73 Compression

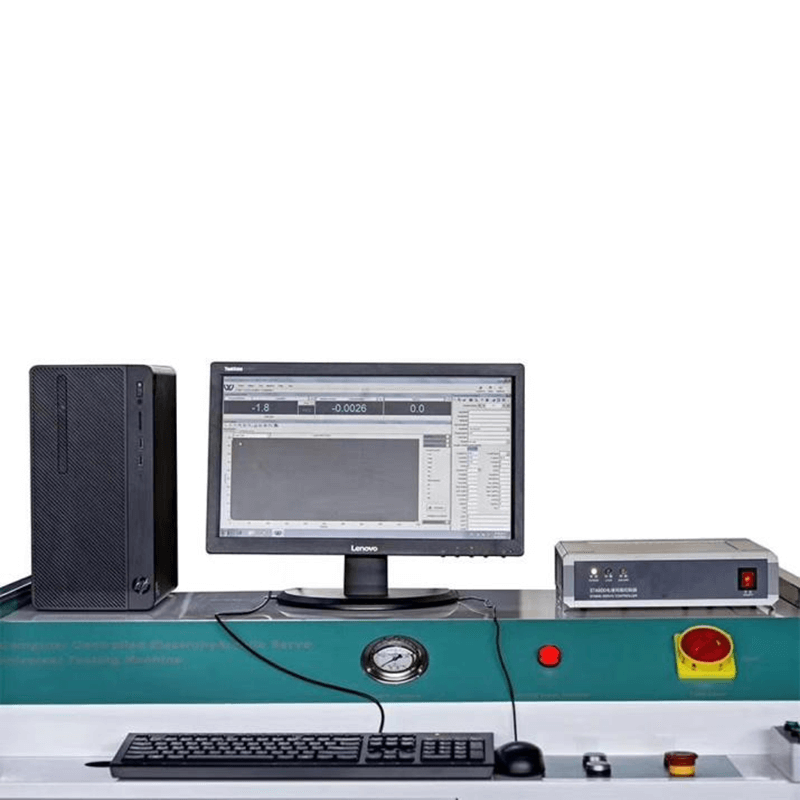

Sistimi ea phetiso

Ho phahamisa le ho theola ha sefapano se tlase ho latela seriti, mokhoa oa phetisetso ea mochine oa ketane, le para ea ho lemoha phetoho ea tsitsipano le sebaka sa likhohlano.

Sistimi ea Hydraulic

Oli ea hydraulic e khakotsoe ke koloi ho khanna pimp ea khatello ea oli, sehlopha sa vala ea li-valve, le phetetso e sa tloaelehang le ho kena. silinda ea oli. K'homphieutha e romela lets'oao la taolo ea valve ea Servo ho laola phallo le sebaka sa Servo, ka ho lelekisa phallo ea matla le ho fallisoa ha velocity.

| Mohlala | Wew-1000b | Wew-1000d |

| Sebopeho | Li-Columente tse 2 | Li-Columente tse 4 |

| 2 screws | 2 screws | |

| Max.load Focce | 1000kn | |

| Teko ea liteko | 2% -100% FS | |

| Qeto ea ho falla (MM) | 0.01 | |

| Mokhoa oa ho otla | Manume Crump kapa Hydraulic o ile a otla | |

| Piston Stroke (limilimithara) (mm) | 200 | |

| Sebaka sa Tense (mm) | 670 | |

| Sebaka sa Compression (MM) | 600 | |

| SIMONE SIRSIMEN CRIME (M) | 13-50 | |

| Metsoako e sephara e bataletseng (limilimithara) | 0-50 | |

| Compression Plete (mm) | Φ200 | |

Li-soulls tsa china: 6-13 / 13-26 / 26-46 / 26- 26-40 / yuniti: mm

Li-hasanels 0-0 / 20-40 / yuniti: mm

Khetho ea likarolo tse tharo

Lipapatso tsa Compression:

Lisekoere-150mm * 150mm

Round 100mm

Round 150mmmm