Kopo

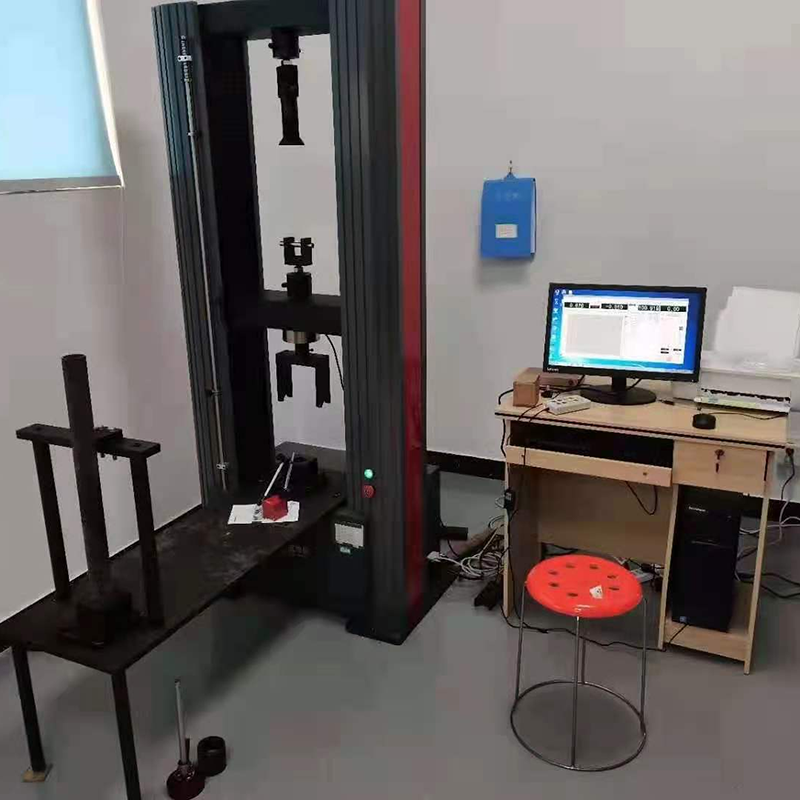

1. Zg-L Serionctor e laoloang ea microcoluteer e laoloang ea microcolute Khomphutha e laola tsamaiso ea taolo ea Ervo Spection le ho potoloha ha enjene ea Servo ka mokhoa oa tšebeliso ea dijithale (karete ea PCI) e hlahisitsoeng ke k'hamphani ea rona. Lebelo la koloi ea AC Serva le felisitsoe ke tsamaiso ea bolo ea themperesion 'me e fetisetsoa ho tla lemoha tensiri, compression le e' ngoe ea mekhoa ea mekhoa eo.

2. Software ea setsebi sa mochini oa tlhahlobo e ka fumana bofokoli ba elalus, ba qobang, matla le matšoao a mang le matšoao a mang. E ka kopana le mokhoa oa ho laola ka kotloloho oa ho tsamaisa thepa khafetsa, khatello ea maikutlo le deformation ea kamehla, 'me ts'ebetso ea tlhahlobo e ka lokisoa le ho laoloa joalo ka ha ho hlokahala tekanyetso. Taolo le ea data ts'ebetso ea liteko ke ts'ebetso ea taolo ea likhomphutha bakeng sa litekanyetso tsa naha tse lumellanang le lisebelisoa tsa tšepe, 'me litlaleho tse ling li arotsoe joalo ka lentsoe, Molao-motheo le mekhoa e meng.

3. Mochine ona ke tšilafalo - MAHALA, o na le lerata le phahameng, e leng katleho e phahameng, 'me e na le molao o mongata oa lebelo. Mochine ona o loketse ho leka thepa ea mechini e fapaneng ea tšepe, bao e seng moeli le lisebelisoa tse kopaneng, 'me ba kopana ka botlalo litlhoko tsa litekanyetso tse loketseng tsa naha.

4. Mochine o sebelisoa haholo tlhahlobong ea lintho tse bonahalang le ho sekaseka thepa, thepa le cable, ho fana ka makoloi le indasteri e meng. E sebelisoa mekhatlong ea lipatlisiso tsa mahlale, liunivesithi tsa mahlale, likhoebo tse likhoebo le tsa merafong, lisebelisoa tse ntle tsa tlhahlobo ea tlhahlobo ea tlhahlobo le libaka tsa ho hlahlojoa.

TLHOKOMELISO

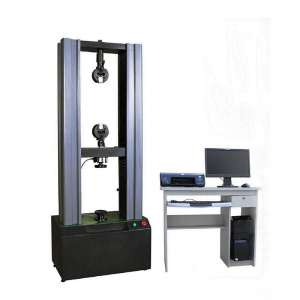

| 1 | Matla a Teko ea Teko | 100KN |

| 2 | Boemo ba mochini oa liteko | Sehlopha sa 1.0 |

| 3 | Tšela maemo a lekanyang | 1% ~ 100% FS (sehlopha sa 1.0) |

| 4 | Phoso e amanang le sesupo | ± 1% (sehlopha sa 1.0) |

| 5 | Qeto ea Sesole ea Teko | 1 / ± 500000fs (qeto e felletseng e sa fetohe) |

| 6 | Mekhahlelo ea Litekanyetso | 0.2% ~ 100% |

| 7 | Matla a taolo ea Start Station | 0.005% ~ 5% FS / S |

| 8 | Matla a taolo laola ho nepahala | Rate <0,05% FS, ± 1%; Ratel0.05% FS, ± 0.5%; |

| 9 | Lenaneo la liphetoho tsa Sekhahla | 0.005 ~ 5% FS / S; |

| 10 | Sekhahla sa Foromo ea Sekhahla sa Deformation | Rate <0,05% FS / S, ± 1%; Ratel0.05% FS / S, ± 0.5%; |

| 11 | Metsoako ea Phetoho ea Bahlahisi | 0.01 ~ 300mmm / mets; |

| 12 | Ho nepahala ha Seteishene sa taolo | ± 0,2%; |

| 13 | Ho qobella ho sa feleng, ho ka etsahala hore o lule o le maemong a taolo | 0.5% ~ 100% FS |

| 14 | Ho hloleha ho sa khaotseng, ho lula u le maemong a teng, ho na le tokelo ea ho laola ho nepahala | ho ipehela0≥10% fs, ± 0.5% ho beha <10% fs, ± 1% |

| 15 | Sebaka se sebetsang sa Teko | 400mm |

| 16 | Ho phatloha pakeng tsa libalaka tse holimo le tse tlase | 650mm |

| 18 | Palo ea li-volts | ~ 220v ± 10% 50hz |

| 19 | Boima ba Machine | 500kg |

LINTHO TSE HLAHANG

1. Mochini oa tlhahlobo ha o silafatse tšilafalo, lerata le tlase, ts'ebetso e bonolo le katleho e phahameng;

2. Mochini o ka sehloohong o adpts aluminum alloy allon, e ntle ebile e mosa;

3. Yuniti ea mantlha ke sebopeho se otlolohileng sa mokato o emeng ka botlalo, ka ts'ebetso e phahameng, ts'ebetso e tsitsitseng le ponahalo e ntle;

4. Ho otlolla le ho qobella

5. Sebopeho sa mantlha se tsitsitse ebile se tšoarella. Seketsoana sa bolo ea bolo e teteaneng le ho tataisa sea le thata, sebali se matla se hlahisa sekhahla se thata se thata, se ka khotsofatsang ka thepa e matla;

6. Li-blams tse holimo le tse tlase tsa mochini o ka sehloohong le ho sebetsa ka mokhoa o sebetsang ho netefatsa ho atile haholo. Ha tlhatlhobo ea axal e etsoa, ho etsa bonnete ba hore lebotho la sampole ka tlas'a mojaro le ameha ka ho fetesisa le khatello ea maikutlo le khatello ea maikutlo le khatello ea maikutlo le khatello ea maikutlo le khatello ea maikutlo le khatello ea maikutlo. ;

7. Sekeche ke seqhetsoana sa bolo ea maoto sa bante, 'me sekoti sa linate se entsoe ka thepa ea koporo e entsoeng ka koporo, e thibelang. Ho se sebetse hantle ha sekoti ho nyane, mokhoa oa ho fetisetsa o phahame, ketsahalo e holimo, 'me matla a phahame;

8. Mokhoa oa ho fokotsa moeli oa ho fokotsa, leboba le otlolohileng le boreleli, le parama e bonolo ea sekoti le thusa sistimi ho ea bohareng;

9. Bakameli ba matla ba phahameng ba nang le matla a bolotsana, likoto tse kentsoe mabanta a boloi Ke boleng ba Mosulus le tsa khatello. E sebetsa haholo ha o ntse o etsa lisebelisoa tse matla tse kang Aerospace e ngata haholo ka tšepe ea tšepe;

10. Ho sebelisa sistimi ea taolo ea koloi le lebelo ho laola ts'ebetso ea liteko, ho nepahala ha taolo ho phahame, ho sebetsa hantle, ho sebetsa hantle

Ha e le hantle, ke lerata ka nako). 'Me ka lebelo la taolo e ngata haholo (0.001-500mmmmmmmmm / min) Lisebelisoa tsa se seng sa tšepe (rabara, filimi, jj.). Ho bonolo ho fetola sebaka sa lekanya kapele ha ho se na mojaro, 'me o boloka nako ea liteko. Lebelo la teko ho kopana le litlhoko tsa hajoale bakeng sa lebelo la teko le lisebelisoa tsohle tsa tšepe China;

11. Lintlha tsa ho hlakisoa ha li-adapthara tsa 'muso li ka bona tlhahlobo ea mochini o fapaneng, e fana ka lisebelisoa tse ngata tse lekang haholoanyane;

12. Thepa ea mahloriso le porono

13. Matlakanyo ea tekanyo ea matla a tsoang sephate e tsoang holimo e ne e bua ka sele ka ho nepahala haholo, ho ba le kutloelo-bohloko e phahameng le ho phetoang hantle. Kamora ho leka-hang, tlhahlobo ha e angoe ke mabotho a kantle, a ka hlalosang ho nepahala ha ts'ebetso ea liteko le liparathara tsa liteko;

14. Taelo ea matla a motho ea shoeleng e tšoana le teropo, khatiso le liteko le ho leka-lekana;

. Boemo ba litlhaloso tse fapaneng li ka hlophisoa ho ea ka litlhokahalo, tse pharalletseng maemo a liteko a ho fihlela litlhoko tsa tekanyo ea meroalo e fapaneng ea liteko;

16. Tekanyo ea deformation e oele ka ho feteletseng ea elektroniki kapa defformation e kholo;

17. Tekanyo ea pokello ea pokello e lemohuoa ke ts'ebetso ea tekanyo ea pokello ea pokello ea basekha ea AC Serva;

18. Tsela e Siretsoeng e se nang mohala e se nang mohala e kopanyang e kenyelletsa mesebetsi e mengata, e sebelisang tšebeliso ea likarolo tsa motlakase ka nepo, 'me ka nepo e fokotsa sekhahla sa motlakase;

19. E ka bona phetoho e potlakileng / e liehang ho phahamisa boroko ha tsela e hapiloeng, 'me ts'ebetso ea fetoha le maemo ebile e ka buloa.

20. Ho na le mosebetsi oa ho khutlela boemong ba pele kamora tlhahlobo, e sebetsang hantle hape e potlakileng;

21. E na le ts'ebetso e phethahetseng ea ts'ireletso, e pharalletseng le tšireletso e fetang ea ho hlahloba ho koala ka sekepe le mesebetsi e meng le e bolokehileng ebile e bolokehile ebile e bolokehile.

22. E na le boemo bo phahameng ba 'mele bo ikemetseng' me ba amohela phetoho ea 'mele ea pigli ea biligital, e ka lemohang khatello ea maikutlo e tloaelehileng e kang khatello ea maikutlo. le khatello ea maikutlo. Mme a ka lemoha ho fetoha setala pakeng tsa mefuta e fapaneng ea taolo ntle le pherekano;

23. Mohato oa ho laola le taolo o na le sephutheloana sa tlhahlobo-leseling ea " Liphetho tsa liteko li ka hlahlojoa le ho sebetsoa ho latela litlhoko tsa mekhoa e fapaneng ea liteko, 'me ts'ebetso ea taolo ea lihlahisoa e sebelisana le mochini e hlophisehileng ea monna e falliselitsoe ho tsamaisa liteko tse ncha. Tekanyetso; E na le tšebetso e matla ea litšoantšo, e ka bonts'a li-curves tsa tlhahlobo le data ea liteko, li-paraphics tsa pele, Mesebetsi e latelang ea ho bonts'a mesebetsi. E na le ts'ebetso ea polokelo ea li-curve tse felletseng tsa liteko le data ea liteko; E na le mesebetsi ea tlhahlobo e le 'ngoe ea tlhahlobo ea tlhahlobo le tlhahiso ea batch ea tlhahlobo le khatiso;

24. Ka sebopeho sa marang-rang, e ka hlokomela marang-rang a data le mesebetsi ea taolo ea hole;

25. Lisebelisoa li theko e boima. Boleng ba lisebelisoa tse kentsoeng thepa, theko ea lisebelisoa tsa lapeng.

Tloaelo

1. GB / T228-2002 "Liaparo tsa Test Ack Room Teen Teko ea Teko ea Teko ea Teko ea Teko

2. GB / 15831-2006 Steel Pipes ea Scaffoldding

3. GB / T5725-2009 "letlo la polokeho"

4.

5. Gb2491111111111111 e hlatsoang ma-stewer e fumanoang

6. GBT 6096- Belt mokhoa oa ts'ireletso oa Belt, GB 5725-2009 polokeho le mekhoa e meng ea polokeho le mekhoa e meng e ka fuoang basebelisi.